| Availability: | |

|---|---|

| Quantity: | |

Composite material cutting machine

Fiber composite materials include glass fibers, carbon fibers, aramid fibers, and prepregs from these kinds of fiber materials. The outstanding properties of fiber composite materials like high strength and low density make them broadly used in aerospace, automobile manufacturing, and many other industries. SLCNC composite material cutting machine has emerged in this field with its unique advantages. It can effectively reduce cutting resistance and reduce material delamination and tearing through high-frequency vibrating blades. During the cutting operation, the cut path and depth can be controlled accurately, ensuring accurate cutting and satisfying the needs of complex shapes of composite materials. Moreover, the vibration knife cutting machine has a very high cutting efficiency and reducing production cost, thus providing overwhelming support to mass application of fiber composite materials. |

What is the prepregs cutting machineSLCNC carbon fiber cutting machine operate based on the high frequency or high-speed motion of the blade. The motor drives the cutting blade to vibrate upwards and downwards or rotate tens of thousands of times a minute. This blade motion makes it effectively cut the fiber composite material. Compared to laser and other conventional cutting processes, SLCNC fiberglass cutting machine has many benefits, like lower cutting force, less heat generation in the cut, better surface quality, more stability in processing, and higher productivity. With the transition of manufacturing industries, traditional cutting methods have exposed limitations. Vibration knife cutting technology came into being. From the initial concept, it has gradually developed into a mature and widely used cutting technology through continuous experiments, improvements, and optimizations. |

SLCNC prepreg cutting machine equipped with a vibrating knife enables it to select various types of cutting tools while, depending on it being carbon, glass, aramid, or prepregs of different fibers, cutting speed can be adjusted to suit particular operations in cutting.

carbon fiber

It has very high specific strength and specific modulus, and its strength and modulus are among the highest in materials available.

When combined with the resin matrix, it will form good performance prepregs.

fiberglass

It has great strength, great modulus, high temperature resistance, and high chemical stability.

Combined with the resin matrix, glass fiber is also used to form high-performance prepregs.

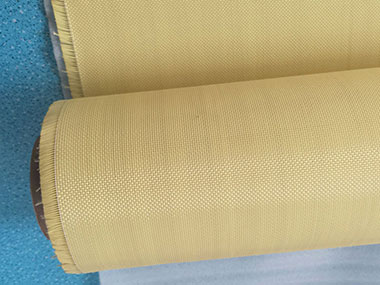

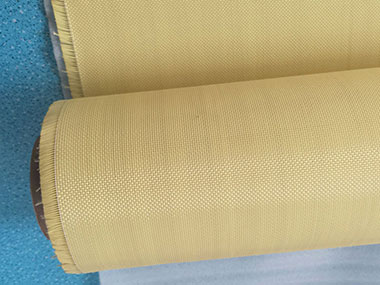

Aramid fiber

Ultra-high strength, high modulus with good heat and impact resistance.

When combined with the resin matrix, aramid will also produce good performance prepregs.

Oscillating knifeThis oscillating knife cuts the fiber composite material by high-frequency vibration. During the cutting process, the up-and-down vibrating frequency of the blade can reach as many as tens of thousands of times per minute, meaning this vibration decreases the resistance during cutting. Vibration is primarily used to cut pre-impregnated composite materials. | |

Rotary knifeThe rotary knife is a whirling tool that driven by a motor, rotates at high speed. The cutting edge of the circular knife moves against the material and cuts the material by the shearing force caused by the rotation. The circular knife is mainly used to cut dry carbon fiber cloth and glass fiber cloth. | |

Milling toolThe milling tool is similar to traditional router. It cuts composite materials by rotating the drill bit and generating relative motion with the material. Milling cutters are used to cut hard composite sheets after curing. |

SLCNC fiberglass cutting machine is equipped with an advanced CNC system that can accurately control the movement path of the cutting tool. It can cut with extremely high precision according to the pre-designed graphics. It meets the complex shape and high-precision dimensional requirements of composite materials.

During the cutting process, the high-frequency vibration characteristics of the vibration knife make the cutting action more stable and delicate. This cutting method can effectively reduce the breakage and pull-out of the fiber, forming a relatively smooth and neat surface. It is conducive to the subsequent processing and assembly process.

The oscillating knife cutting machine is a mechanical cutting method, which does not generate high heat like laser cutting. It avoids the softening and decomposition of the matrix resin or the change of fiber properties caused by high temperature. Thereby protecting the physical and chemical properties of fiber composite materials.

This glass fiber cutting machine features a very fast cutting speed, up to tens of meters per minute, which hugely improves production efficiency. Meanwhile, with an advanced feeding system and optimized software for the cutting route, pauses and idling in the process will be reduced.

Save materialSLCNC carbon cloth cutting machine is equipped with intelligent typesetting software. When cutting fiber composite materials, the software can automatically make the optimal layout according to the size of the material and the shape to be cut. Reduce material waste and reduce production costs. |  |

The operation of SLCNC composite material cutting machine is very simple and does not require much professional skills and knowledge. Design the CAD drawings for cutting. Import the drawings into the machine and it will be cut automatically.

Design CAD drawings

Automatically cutting

| Protection equipmentIt can be used to make protective equipment such as bulletproof vests, helmets, protective gloves, and protective gear. Not only can it withstand impact force to protect personal safety, but it can also reduce the burden of wearing it and make it more comfortable. |

| Aerospace industryIt finds wide application in structural parts such as wings, fuselage, and the tail of an aircraft. This greatly reduces the overall weight of the aircraft, and fuel consumption, while at the same time improving structural strength and resistance to fatigue. |

| Automotive industryUsed on body parts, bumpers of cars, etc.; compared to the traditional metal material, composite parts can have a weight reduction of 30%-50%, thereby improving the fuel economy and accelerating the performance of cars. |

| Sports goodsApplied in manufacturing high-class sports goods such as golf clubs, tennis rackets, bicycle frames, etc. Carbon fiber's high modulus and lightness can make sporting goods lighter and more flexible while maintaining high intensity. |

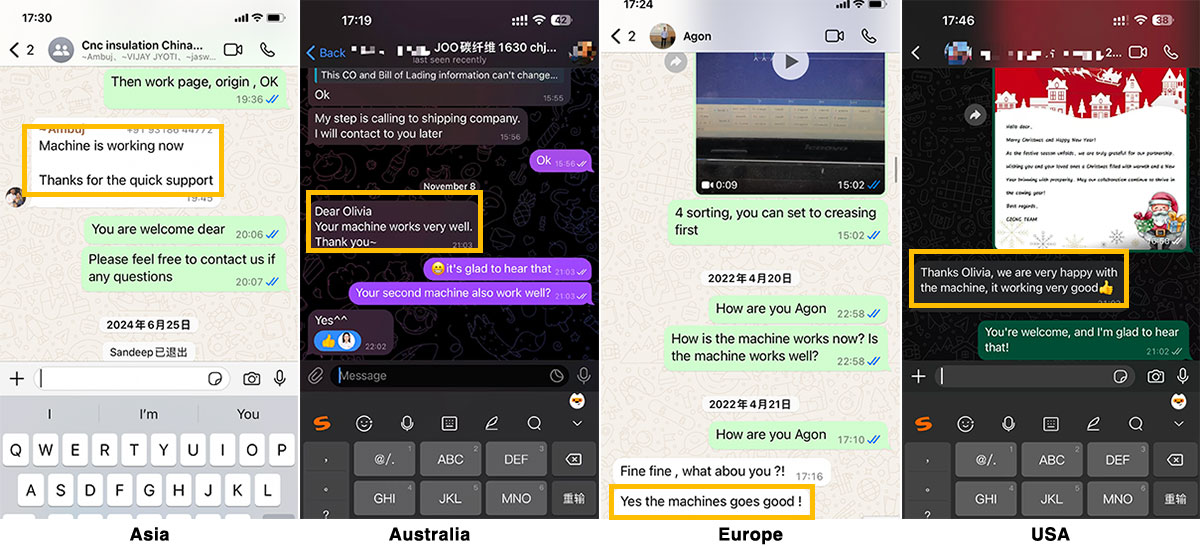

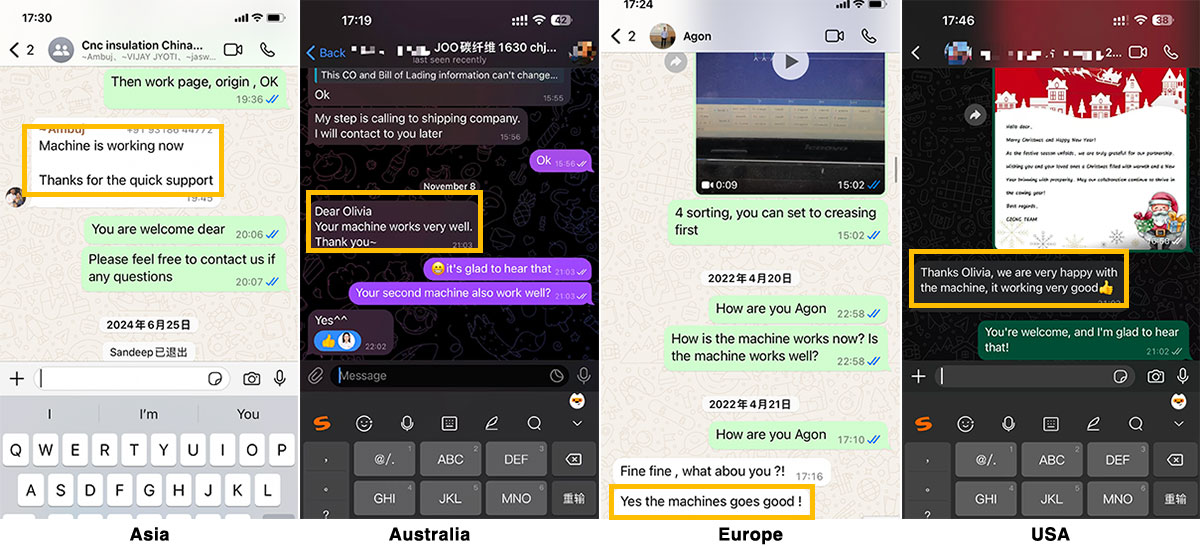

3 years warranty

24-hour online service

1. Training service

You will get high-quality operation training after you get the SLCNC glass fiber cutting machine.

2. Maintenance service

The after-sales team will provide fast-response maintenance services.

3. Upgrade service

Our after-sales team will provide upgrade services for our fiberglass cloth cutting machine.

SLCNC has an excellent team, including a design, sales, production, and after-sales team. We ensure that every step is professional. We provide professional services from consulting the machine to ordering, shipping, and after-sales.

We can customize the machine size, tool combination, etc. to meet the customer's cutting requirements of different materials and sizes. In addition, we have rich experience in many industries and can recommend the correct machine configuration and auxiliary devices to you.

1. Training service

You will get high-quality operation training after you get the SLCNC carbon fiber cutting machine.

2. Maintenance service

The after-sales team will provide fast-response maintenance services.

3. Upgrade service

Our after-sales team will provide upgrade services for our fiberglass cutting machine.

Composite material cutting machine

Fiber composite materials include glass fibers, carbon fibers, aramid fibers, and prepregs from these kinds of fiber materials. The outstanding properties of fiber composite materials like high strength and low density make them broadly used in aerospace, automobile manufacturing, and many other industries. SLCNC composite material cutting machine has emerged in this field with its unique advantages. It can effectively reduce cutting resistance and reduce material delamination and tearing through high-frequency vibrating blades. During the cutting operation, the cut path and depth can be controlled accurately, ensuring accurate cutting and satisfying the needs of complex shapes of composite materials. Moreover, the vibration knife cutting machine has a very high cutting efficiency and reducing production cost, thus providing overwhelming support to mass application of fiber composite materials. |

What is the prepregs cutting machineSLCNC carbon fiber cutting machine operate based on the high frequency or high-speed motion of the blade. The motor drives the cutting blade to vibrate upwards and downwards or rotate tens of thousands of times a minute. This blade motion makes it effectively cut the fiber composite material. Compared to laser and other conventional cutting processes, SLCNC fiberglass cutting machine has many benefits, like lower cutting force, less heat generation in the cut, better surface quality, more stability in processing, and higher productivity. With the transition of manufacturing industries, traditional cutting methods have exposed limitations. Vibration knife cutting technology came into being. From the initial concept, it has gradually developed into a mature and widely used cutting technology through continuous experiments, improvements, and optimizations. |

SLCNC prepreg cutting machine equipped with a vibrating knife enables it to select various types of cutting tools while, depending on it being carbon, glass, aramid, or prepregs of different fibers, cutting speed can be adjusted to suit particular operations in cutting.

carbon fiber

It has very high specific strength and specific modulus, and its strength and modulus are among the highest in materials available.

When combined with the resin matrix, it will form good performance prepregs.

fiberglass

It has great strength, great modulus, high temperature resistance, and high chemical stability.

Combined with the resin matrix, glass fiber is also used to form high-performance prepregs.

Aramid fiber

Ultra-high strength, high modulus with good heat and impact resistance.

When combined with the resin matrix, aramid will also produce good performance prepregs.

Oscillating knifeThis oscillating knife cuts the fiber composite material by high-frequency vibration. During the cutting process, the up-and-down vibrating frequency of the blade can reach as many as tens of thousands of times per minute, meaning this vibration decreases the resistance during cutting. Vibration is primarily used to cut pre-impregnated composite materials. | |

Rotary knifeThe rotary knife is a whirling tool that driven by a motor, rotates at high speed. The cutting edge of the circular knife moves against the material and cuts the material by the shearing force caused by the rotation. The circular knife is mainly used to cut dry carbon fiber cloth and glass fiber cloth. | |

Milling toolThe milling tool is similar to traditional router. It cuts composite materials by rotating the drill bit and generating relative motion with the material. Milling cutters are used to cut hard composite sheets after curing. |

SLCNC fiberglass cutting machine is equipped with an advanced CNC system that can accurately control the movement path of the cutting tool. It can cut with extremely high precision according to the pre-designed graphics. It meets the complex shape and high-precision dimensional requirements of composite materials.

During the cutting process, the high-frequency vibration characteristics of the vibration knife make the cutting action more stable and delicate. This cutting method can effectively reduce the breakage and pull-out of the fiber, forming a relatively smooth and neat surface. It is conducive to the subsequent processing and assembly process.

The oscillating knife cutting machine is a mechanical cutting method, which does not generate high heat like laser cutting. It avoids the softening and decomposition of the matrix resin or the change of fiber properties caused by high temperature. Thereby protecting the physical and chemical properties of fiber composite materials.

This glass fiber cutting machine features a very fast cutting speed, up to tens of meters per minute, which hugely improves production efficiency. Meanwhile, with an advanced feeding system and optimized software for the cutting route, pauses and idling in the process will be reduced.

Save materialSLCNC carbon cloth cutting machine is equipped with intelligent typesetting software. When cutting fiber composite materials, the software can automatically make the optimal layout according to the size of the material and the shape to be cut. Reduce material waste and reduce production costs. |  |

The operation of SLCNC composite material cutting machine is very simple and does not require much professional skills and knowledge. Design the CAD drawings for cutting. Import the drawings into the machine and it will be cut automatically.

Design CAD drawings

Automatically cutting

| Protection equipmentIt can be used to make protective equipment such as bulletproof vests, helmets, protective gloves, and protective gear. Not only can it withstand impact force to protect personal safety, but it can also reduce the burden of wearing it and make it more comfortable. |

| Aerospace industryIt finds wide application in structural parts such as wings, fuselage, and the tail of an aircraft. This greatly reduces the overall weight of the aircraft, and fuel consumption, while at the same time improving structural strength and resistance to fatigue. |

| Automotive industryUsed on body parts, bumpers of cars, etc.; compared to the traditional metal material, composite parts can have a weight reduction of 30%-50%, thereby improving the fuel economy and accelerating the performance of cars. |

| Sports goodsApplied in manufacturing high-class sports goods such as golf clubs, tennis rackets, bicycle frames, etc. Carbon fiber's high modulus and lightness can make sporting goods lighter and more flexible while maintaining high intensity. |

3 years warranty

24-hour online service

1. Training service

You will get high-quality operation training after you get the SLCNC glass fiber cutting machine.

2. Maintenance service

The after-sales team will provide fast-response maintenance services.

3. Upgrade service

Our after-sales team will provide upgrade services for our fiberglass cloth cutting machine.

SLCNC has an excellent team, including a design, sales, production, and after-sales team. We ensure that every step is professional. We provide professional services from consulting the machine to ordering, shipping, and after-sales.

We can customize the machine size, tool combination, etc. to meet the customer's cutting requirements of different materials and sizes. In addition, we have rich experience in many industries and can recommend the correct machine configuration and auxiliary devices to you.

1. Training service

You will get high-quality operation training after you get the SLCNC carbon fiber cutting machine.

2. Maintenance service

The after-sales team will provide fast-response maintenance services.

3. Upgrade service

Our after-sales team will provide upgrade services for our fiberglass cutting machine.