| Availability: | |

|---|---|

| Quantity: | |

SLCNC Leather CNC Knife Cutting MachineAs the consumer market's demand for personalized, high-quality leather products continues to rise, traditional cutting processes are increasingly unable to cope. At this time, the SLCNC leather cutting machine came into being. It uses the principle of mechanical vibration to cut leather through a high-frequency vibrating blade, and the cutting process is neat and precise. Whether it is cutting complex patterns, special-shaped contours, or dealing with irregular-shaped leather, it shows excellent performance. Inject new vitality into leather processing and open a new chapter of efficiency, precision, and environmental protection. |

What is Genuine Leather Cutting Machine

What is Genuine Leather Cutting MachineSLCNC genuine leather cutting machine is a modern equipment for professional cutting leather. It consists of the machine body, the motion system, the CNC system, the cutting tools, and auxiliary accessories.

The machine body is the support frame to ensure the stability of the entire equipment.

The worktable is used to place leather and has an adsorption function to fix the leather firmly.

The CNC system converts the information input by the operator into instructions for the machine to work and accurately controls the cutting path.

The cutting tool is the core component, which uses a high-frequency vibration knife to cut leather.

Genuine leather system is professional to handle the genuine leather like extract outlines, avoid defects, layout, etc.

Model | CZ - 1625 |

Work Size | 1600mm x 2500mm/other size |

Table Type | auto feeding table / flat table |

Warranty | 3 years for machines |

Cut Speed | ≤ 1600 mm/s |

Cut Thickness | ≤ 45mm |

Location Precision | ≤ 0.01mm |

Safety Device | infrared sensors, responsive, safe and reliable. |

Material Fixed Mode | vacuum table |

Support software | Corel draw, AI, Auto cad and etc |

Motor and Driver | Japan Yaskawa / Panasonic |

Support Format | plt, ai, dxf, cdr, hpg, hpgl, etc |

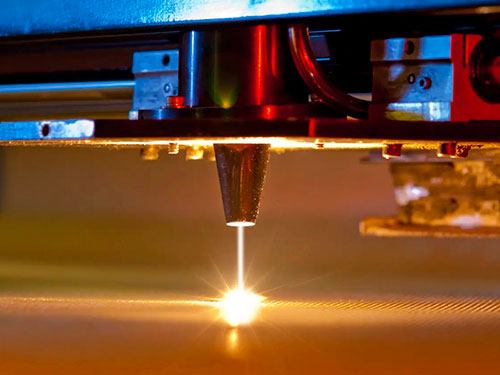

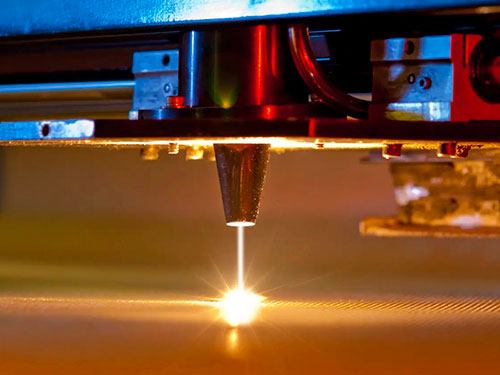

The vibrating knife is the core tool of SLCNC leather cutting machine. It cuts leather with a high-frequency vibrating blade. Driven by the motor, the blade can vibrate tens of thousands of times per second. This high-frequency vibration reduces the resistance of the blade when cutting leather. This makes the incision smooth and flat, greatly improving the cutting quality.

The CNC system drives the punching tool to rotate at high speed and press vertically down to drill the required holes in the leather. It can punch holes of different diameters according to design requirements. The punching process is fast and accurate, and will not cause tearing or deformation around the leather.

The marking pen can gently draw clear and continuous lines on the leather surface. This can provide accurate references for subsequent processes. Whether it is a complex pattern or a letter, it can be easily done. The pressure of the marking pen can be adjusted. This can ensure that a clear mark is left on the leather without scratching it.

| Manual cutting Low precision. Manual cutting has low accuracy. Complex patterns are difficult to cut, and the curve cutting is irregular. Low efficiency. When facing mass production tasks, manual cutting will greatly extend the entire production time. High risk. Manual cutting has high safety risks, and sharp knives is easily scratch hands. |

| Laser cutting machine Laser cutting machine uses high energy laser beams to cut leather. It can meet the requirements of leather cutting for precision and efficiency. Heat damage: The high temperature of the laser will cause heat damage to the leather cutting edge, making the cutting edge harden or discolor. Safety risk: The laser beam has high energy and there is a risk of harming personnel. And open flames may be generated during the cutting process, causing fire risks. |

| Hydraulic die cutting machine Hydraulic die-cutting machines are efficient in cutting leather. However, a large number of molds need to be made. High molds cost . Hydraulic die-cutting machines need to customize special molds according to different cutting needs. A large number of customized molds will greatly increase costs. Safety hazards. When placing the cutting mold on leather, it poses a threat to the personal safety of the operator. |

| High PrecisionWith its advanced mechanical structure and precision CNC system, the cutting accuracy of SLCNC genuine leather cutting machine can be stably controlled within millimeters. Even when cutting irregular graphics such as arcs, there is almost no dimensional deviation. Precise cutting ensures perfect splicing of each piece and ensures the beauty of the leather product. |

| High Efficient and flexibleThe cutting speed of SLCNC leather CNC cutting machine can reach 30 meters per minute. It is dozens of times more efficient than traditional manual cutting. At the same time, it gets rid of the constraints of the mold, and can respond quickly and cut immediately when facing new designs or small batch custom orders. Enterprises can quickly bring products to market and seize the opportunity. |

| Environmental protection and safetySLCNC leather cutter machine adopts mechanical cold cutting method. During the leather cutting process, no pungent smoke and burnt smell similar to laser cutting will be produced throughout the process. It avoids air pollution in the workshop and meets environmental protection requirements. And effectively ensures the health of workers. |

| Multi-function toolsSLCNC cowhide cutting machine can be equipped with a variety of tools, such as cutting tools, punching tools, and brush tools. Our genuine leather cutting machine can achieve multiple functions such as marking, punching, and cutting of leather. Meet the diverse processing requirements of the leather industry. Facilitate subsequent splicing and stitching operations. |

| Improve leather utilizationSLCNC leather cutter machine has professional layout software. It can automatically layout the cut pieces in irregular leather contours to improve leather utilization. In addition, the cutting position of our leather cutting machine is accurate, and the gap between the cut pieces is small to reduce leather waste. Reduce production costs. |

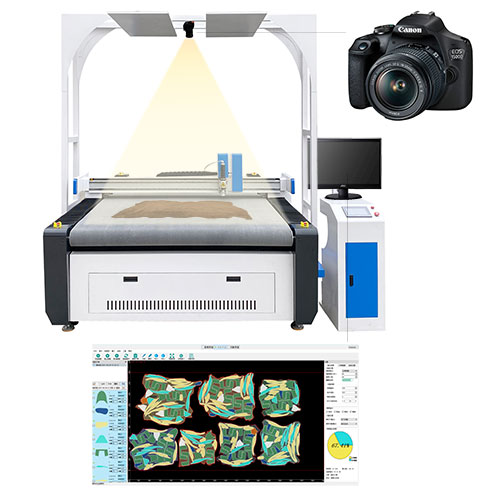

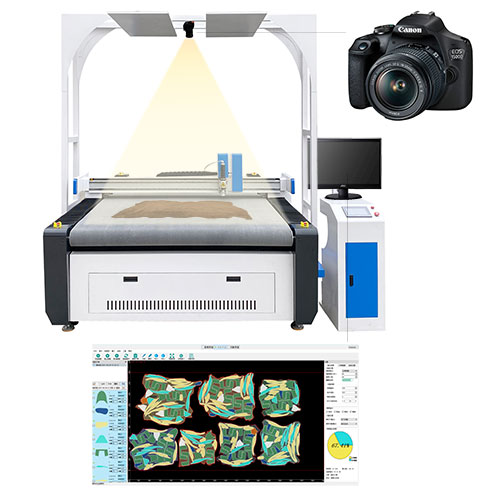

The leather system is the core of SLCNC leather CNC cutting machine. Mainly includes industrial cameras and professional software. It is responsible for the scanning, defect avoidance, layout and other pre-cutting preparations of the leather. It plays a key role in improving leather utilization and simplifying the cutting process.

Leather is irregular, so it is necessary to obtain the outer contour of the leather first to constrain the subsequent layout range. In addition, it can guide the subsequent cutting position of the machine.

Leather vision software can accurately identify a variety of defects, and can intelligently avoid leather defects for layout, improve leather utilization. Provide accurate location information for layout.

Through functions such as intelligent layout and automatic tiling, the leather utilization rate is improved. and the waste of leather is reduced, thereby reducing production costs.

SLCNC leather digital cutting machines play a key role in multiple leather application industries.

In the field of shoemaking, it can accurately cut leather materials of different styles of leather shoes, ensure accurate pattern, and improve shoe quality and production efficiency.

In the leather goods industry, whether it is a bag, belt or wallet, SLCNC cowhide cutting machine can quickly and finely cut leather, realize complex design, and meet personalized needs.

In the furniture industry, it also has an outstanding performance in leather cutting for leather sofas and leather chairs, helping the industry to develop efficiently.

Shoes

Clothing

Sofas

Luggage

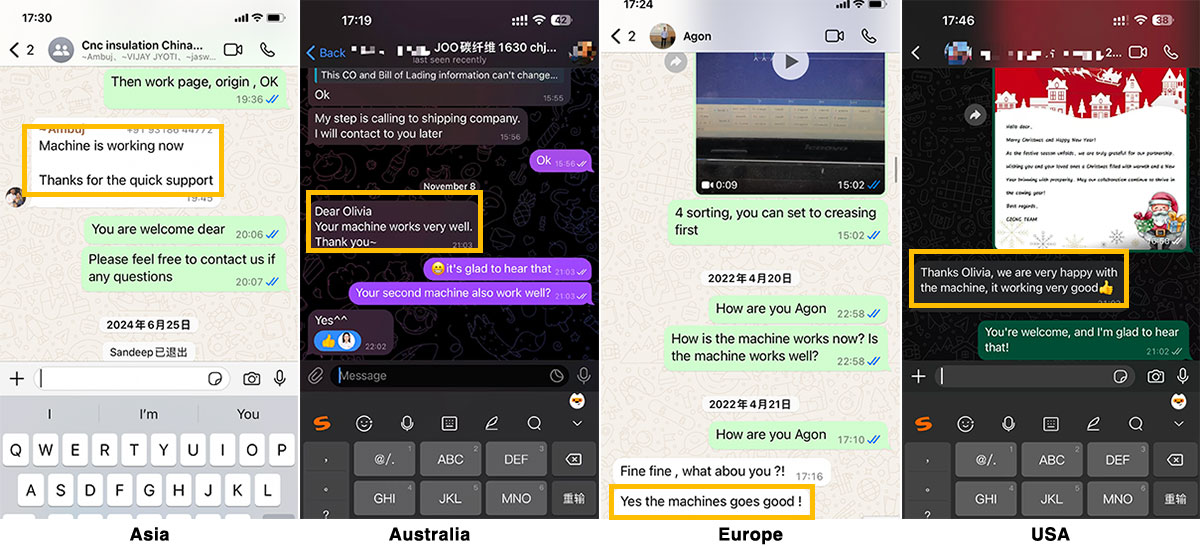

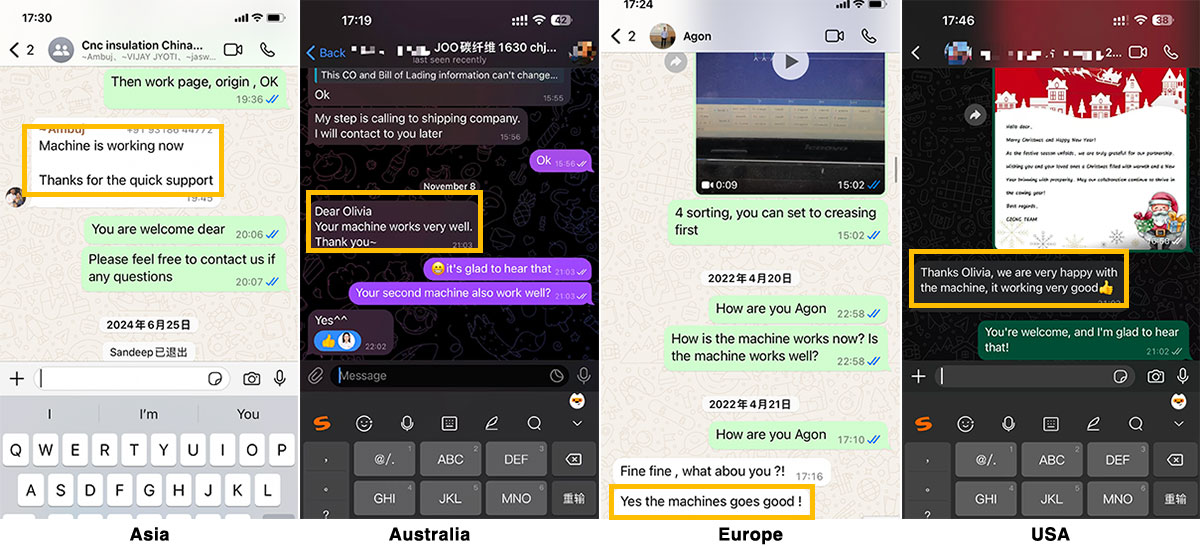

SLCNC has an excellent team, including a design, sales, production, and after-sales team. We ensure that every step is professional. We provide professional services from consulting the machine to ordering, shipping, and after-sales.

We can customize the machine size, tool combination, etc. to meet the customer's cutting requirements of different materials and sizes. In addition, we have rich experience in many industries and can recommend the correct machine configuration and auxiliary devices to you.

1. Training service

You will get high-quality operation training after you get the CZCNC leather cutting machine.

2. Maintenance service

The after-sales team will provide fast-response maintenance services.

3. Upgrade service

Our after-sales team will provide upgrade services for our leather cutting machine.

SLCNC Leather CNC Knife Cutting MachineAs the consumer market's demand for personalized, high-quality leather products continues to rise, traditional cutting processes are increasingly unable to cope. At this time, the SLCNC leather cutting machine came into being. It uses the principle of mechanical vibration to cut leather through a high-frequency vibrating blade, and the cutting process is neat and precise. Whether it is cutting complex patterns, special-shaped contours, or dealing with irregular-shaped leather, it shows excellent performance. Inject new vitality into leather processing and open a new chapter of efficiency, precision, and environmental protection. |

What is Genuine Leather Cutting Machine

What is Genuine Leather Cutting MachineSLCNC genuine leather cutting machine is a modern equipment for professional cutting leather. It consists of the machine body, the motion system, the CNC system, the cutting tools, and auxiliary accessories.

The machine body is the support frame to ensure the stability of the entire equipment.

The worktable is used to place leather and has an adsorption function to fix the leather firmly.

The CNC system converts the information input by the operator into instructions for the machine to work and accurately controls the cutting path.

The cutting tool is the core component, which uses a high-frequency vibration knife to cut leather.

Genuine leather system is professional to handle the genuine leather like extract outlines, avoid defects, layout, etc.

Model | CZ - 1625 |

Work Size | 1600mm x 2500mm/other size |

Table Type | auto feeding table / flat table |

Warranty | 3 years for machines |

Cut Speed | ≤ 1600 mm/s |

Cut Thickness | ≤ 45mm |

Location Precision | ≤ 0.01mm |

Safety Device | infrared sensors, responsive, safe and reliable. |

Material Fixed Mode | vacuum table |

Support software | Corel draw, AI, Auto cad and etc |

Motor and Driver | Japan Yaskawa / Panasonic |

Support Format | plt, ai, dxf, cdr, hpg, hpgl, etc |

The vibrating knife is the core tool of SLCNC leather cutting machine. It cuts leather with a high-frequency vibrating blade. Driven by the motor, the blade can vibrate tens of thousands of times per second. This high-frequency vibration reduces the resistance of the blade when cutting leather. This makes the incision smooth and flat, greatly improving the cutting quality.

The CNC system drives the punching tool to rotate at high speed and press vertically down to drill the required holes in the leather. It can punch holes of different diameters according to design requirements. The punching process is fast and accurate, and will not cause tearing or deformation around the leather.

The marking pen can gently draw clear and continuous lines on the leather surface. This can provide accurate references for subsequent processes. Whether it is a complex pattern or a letter, it can be easily done. The pressure of the marking pen can be adjusted. This can ensure that a clear mark is left on the leather without scratching it.

| Manual cutting Low precision. Manual cutting has low accuracy. Complex patterns are difficult to cut, and the curve cutting is irregular. Low efficiency. When facing mass production tasks, manual cutting will greatly extend the entire production time. High risk. Manual cutting has high safety risks, and sharp knives is easily scratch hands. |

| Laser cutting machine Laser cutting machine uses high energy laser beams to cut leather. It can meet the requirements of leather cutting for precision and efficiency. Heat damage: The high temperature of the laser will cause heat damage to the leather cutting edge, making the cutting edge harden or discolor. Safety risk: The laser beam has high energy and there is a risk of harming personnel. And open flames may be generated during the cutting process, causing fire risks. |

| Hydraulic die cutting machine Hydraulic die-cutting machines are efficient in cutting leather. However, a large number of molds need to be made. High molds cost . Hydraulic die-cutting machines need to customize special molds according to different cutting needs. A large number of customized molds will greatly increase costs. Safety hazards. When placing the cutting mold on leather, it poses a threat to the personal safety of the operator. |

| High PrecisionWith its advanced mechanical structure and precision CNC system, the cutting accuracy of SLCNC genuine leather cutting machine can be stably controlled within millimeters. Even when cutting irregular graphics such as arcs, there is almost no dimensional deviation. Precise cutting ensures perfect splicing of each piece and ensures the beauty of the leather product. |

| High Efficient and flexibleThe cutting speed of SLCNC leather CNC cutting machine can reach 30 meters per minute. It is dozens of times more efficient than traditional manual cutting. At the same time, it gets rid of the constraints of the mold, and can respond quickly and cut immediately when facing new designs or small batch custom orders. Enterprises can quickly bring products to market and seize the opportunity. |

| Environmental protection and safetySLCNC leather cutter machine adopts mechanical cold cutting method. During the leather cutting process, no pungent smoke and burnt smell similar to laser cutting will be produced throughout the process. It avoids air pollution in the workshop and meets environmental protection requirements. And effectively ensures the health of workers. |

| Multi-function toolsSLCNC cowhide cutting machine can be equipped with a variety of tools, such as cutting tools, punching tools, and brush tools. Our genuine leather cutting machine can achieve multiple functions such as marking, punching, and cutting of leather. Meet the diverse processing requirements of the leather industry. Facilitate subsequent splicing and stitching operations. |

| Improve leather utilizationSLCNC leather cutter machine has professional layout software. It can automatically layout the cut pieces in irregular leather contours to improve leather utilization. In addition, the cutting position of our leather cutting machine is accurate, and the gap between the cut pieces is small to reduce leather waste. Reduce production costs. |

The leather system is the core of SLCNC leather CNC cutting machine. Mainly includes industrial cameras and professional software. It is responsible for the scanning, defect avoidance, layout and other pre-cutting preparations of the leather. It plays a key role in improving leather utilization and simplifying the cutting process.

Leather is irregular, so it is necessary to obtain the outer contour of the leather first to constrain the subsequent layout range. In addition, it can guide the subsequent cutting position of the machine.

Leather vision software can accurately identify a variety of defects, and can intelligently avoid leather defects for layout, improve leather utilization. Provide accurate location information for layout.

Through functions such as intelligent layout and automatic tiling, the leather utilization rate is improved. and the waste of leather is reduced, thereby reducing production costs.

SLCNC leather digital cutting machines play a key role in multiple leather application industries.

In the field of shoemaking, it can accurately cut leather materials of different styles of leather shoes, ensure accurate pattern, and improve shoe quality and production efficiency.

In the leather goods industry, whether it is a bag, belt or wallet, SLCNC cowhide cutting machine can quickly and finely cut leather, realize complex design, and meet personalized needs.

In the furniture industry, it also has an outstanding performance in leather cutting for leather sofas and leather chairs, helping the industry to develop efficiently.

Shoes

Clothing

Sofas

Luggage

SLCNC has an excellent team, including a design, sales, production, and after-sales team. We ensure that every step is professional. We provide professional services from consulting the machine to ordering, shipping, and after-sales.

We can customize the machine size, tool combination, etc. to meet the customer's cutting requirements of different materials and sizes. In addition, we have rich experience in many industries and can recommend the correct machine configuration and auxiliary devices to you.

1. Training service

You will get high-quality operation training after you get the CZCNC leather cutting machine.

2. Maintenance service

The after-sales team will provide fast-response maintenance services.

3. Upgrade service

Our after-sales team will provide upgrade services for our leather cutting machine.