Views: 298 Author: Site Editor Publish Time: 2022-03-18 Origin: Site

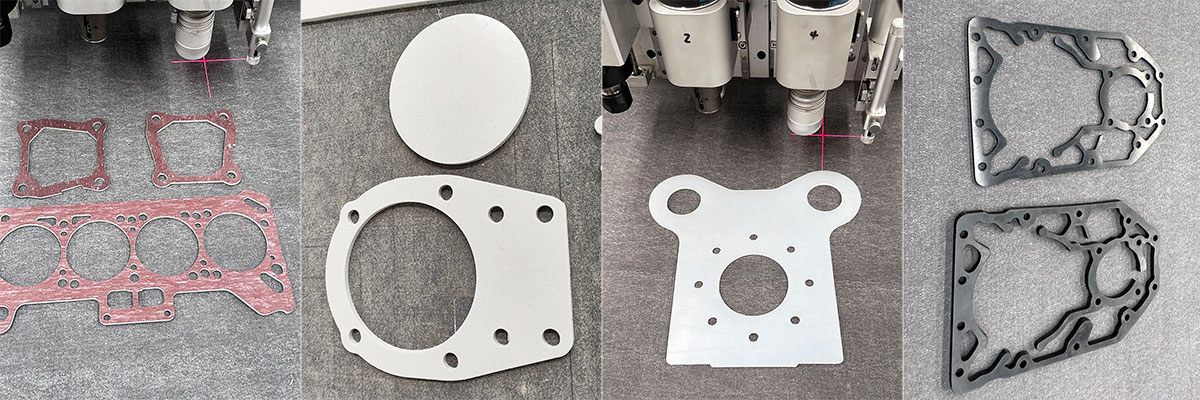

Gaskets play important components in various fields for modern industries. The automated gasket cutter machine has become the ideal choice for gasket making with its unique advantages.

The sealing gasket is used between two connection parts and to prevent leakage. The accuracy requirement is very high. The gasket CNC cutting machine adopts advanced CNC technology. It can accurately control the cutting path and size, ensuring that the gasket's dimensional accuracy reaches the millimeter level or even higher. During the cutting process, the high vibration frequency and low amplitude of the cutter make the cutting line smoother and cleaner. this avoids the size deviation and edge burr that may occur in traditional cutting methods. This high-precision cutting ensures a tight fit between the gasket and the sealing part. Effectively improving the sealing performance.

The laser cutting machine can also cut some gaskets. but laser generates a large amount of heat during the cutting process. High temperatures can lead to thermal deformation. the deformation will affect its physical properties and sealing performance. In contrast, the gasket making machine do not generate heat during the cutting process. So it can avoid the problem of thermal deformation. This is particularly important for some temperature sensitive gasket materials such as rubber and silicone. meanwhile, the cutting method without thermal deformation ensures that the edge of the gasket material is not damaged. thus ensuring its stable performance and prolonging its service life.

There are many kinds of gasket materials, including rubber, silicone, plastic, leather, fabric, etc. The gasket maker machine can install different cutting tools. so can deal with these materials easily.

Production efficiency is very important to enterprises. The gasket cutting machine has fast cutting speed and a high degree of automation. So can greatly improve the gasket production efficiency. The gasket making tool can work continuously without stopping. Reduce the time and labor intensityand improve production efficiency.

The gasket CNC cutter machine doesn't generate dust or pollution in the cutting process. meanwhile, the energy consumption of the gasket cutter machine is low. It can save a lot of energy. This reduces the production cost of enterprises.

The CNC gasket cutter machine can cut a variety of shapes. According to the customer's electronic graphics, or according to the electronic graphics provided by the customer, the gasket can be easily cut out.

The automatic gasket cutting machine has become an ideal choice for custom gasket cutting. The major advantages are high precision cutting, no thermal deformation, wide material applicability, high cutting efficiency, environmental protection and energy saving, and flexible cutting methods. In future industrial production, the vibratory knife cutting machine will continue to play its important role and make more contributions to the development of the gasket industry.