| Availability: | |

|---|---|

| Quantity: | |

|

|

|

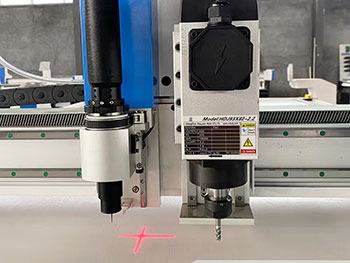

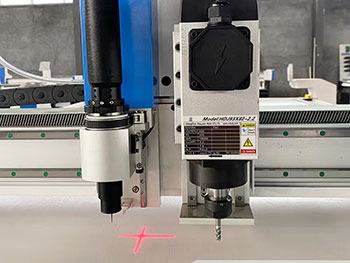

Multifunctional toolsThe combined cutter tools can cut wide range gaskets of various materials, hardness, and thickness | Fully welded bodyWelded from square steel tubes, heat treated, and milled on five sides. Ensure the accuracy and strength of the body | Vacuum tableThe overall aluminum bellows table with a thickness of 40mm. High strength, high precision, and strong adsorption force. |

|

|

|

High-precision guide railSLCNC gasket cutter machine adopts high-precision racks and guide rails. High accuracy, wear resistance, and low noise. | Servo motors and driversSLCNC gasket cutting machine uses Japanese servo motor and driver, high precision, long life, and high torque. | Vacuum pumpHigh suction vacuum pump, strong suction, firm fixing of materials. With a muffler to reduce noise. |

|

|

|

Safety devicesThere are four corners emergency stop switches and infrared induction switches to protect the operator and the machine. | CNC SystemThe touch screen integrates the settings and operations, the gasket cutter machine is simple and convenient to use, supports multiple languages | Wooden PackagingThe complete equipment is packed in a fumigation-free wooden box to protect the machine from damage during transportation. |

Gaskets are widely used in industry and play an important role. Gaskets are used in mechanical equipment and pipelines as long as there is fluid. Gasket material includes rubber, silicone, asbestos, asbestos, PTFE, non-asbestos and other materials. SLCNC gasket cutter machine can cut these non-metallic gaskets very well.

SLCNC gasket cutting machine can be equipped with multiple cutting tools at the same time. Because the thickness and hardness of the gasket vary, the cutting tools required are different. Our gasket making machine can combine multiple cutting tools together to meet your wider cutting requirements.

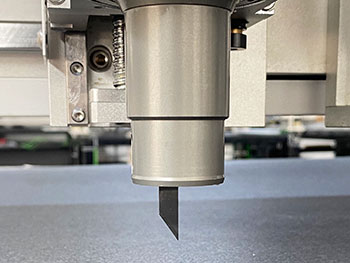

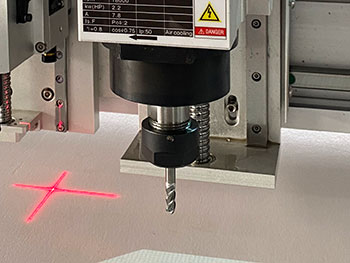

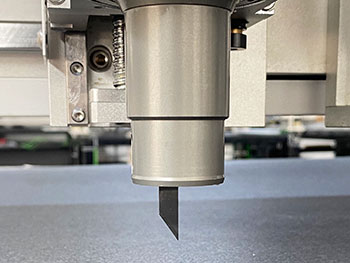

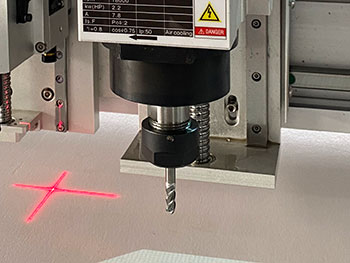

Cutting tool combination

The combination tool broadens the cutting range of gaskets. No matter thick or thin, hard or soft, one SLCNC gasket cutting machine can cut them all.

Knife cutting tool

Used to cut soft, hard but thin gasket materials, such as rubber, silicone, and thin asbestos.

Milling cutting tool

Used for cutting hard and thick materials, such as thicker PTFE, asbestos, etc.

| Easy operation The CNC gasket cutting machine is a CNC knife cutting machine. Unlike the die-cutting processing method, it does not require a mold. Only CAD electronic graphics are needed to automatically cut gaskets of various shapes by a knife blade. For customized and small batch gasket production, it can shorten the production cycle, save the cost of molds, and graphic storage is much simpler and more convenient than mold storage. |

| High precision SLCNC gasket CNC cutting machine adopts a high-speed drive and transmission method. Japanese servo motors and drives, Taiwan guide rails and helical racks ensure the accuracy and efficiency of processing. And ensure that the equipment has a long service life and a low failure rate. |

Material automatic fixing SLCNC automatic gasket cutting machine uses vacuum adsorption to fix the material. The vacuum pump automatically starts and stops with the cutting process. When the cutting starts, the vacuum pump automatically starts, and when the cutting ends, the vacuum pump automatically stops. This way of fixing the material is simple and convenient, and will not damage the material. | |

| Safety SLCNC gasket making machine does not require manual operation during the cutting process. It not only saves labor costs, but is also safer. In addition, the machine is equipped with a four-corner emergency stop switch and an infrared sensor switch. Ensure the safety of operators and equipment. |

| Nesting software saves material SLCNC gasket cutting equipment has automatic nesting software that can control parameters such as the gap of typesetting. The material utilization rate can be calculated, and the material utilization rate can be improved to reduce production costs. |

Model | CZ - 1625 |

Work Size | 1600mm x 2500mm/other size |

Cutting Table | auto feeding table / flat table |

Warranty | 3 years for machines |

Cut Speed | ≤ 1600 mm/s |

Cut Thickness | ≤ 100mm |

Location Precision | ≤ 0.01mm |

Safety Device | infrared sensors, responsive, safe and reliable. |

Material Fixed Mode | vacuum table |

Support software | Corel draw, AI, Auto cad and etc |

Motor and Driver | Japan Yaskawa / Panasonic |

Support Format | plt, ai, dxf, cdr, hpg, hpgl, etc |

| Precision designSLCNC has a professional design team. The whole gasket cutting machine and each component are carefully designed. Ensure that the mechanical structure of the machine is reasonable, the rigidity and precision of the components meet the production requirements, and are easy to install and repair in the future. |

| Precision machiningThe installation surface of the bed is processed by five-sided milling to provide a high-precision benchmark for subsequent installation. The installation parts on the machine, such as the motor seat, and the connecting parts, such as the gantry bracket, are all processed by the CNC machining center to ensure the accuracy of the machine parts. |

| Precision installationSLCNC has a stable and skilled production team. There are strict technical requirements for the installation of components. The installation accuracy of the transmission components is measured and debugged by a dial indicator to ensure the installation accuracy of the machine. |

| Precision testingSLCNC has professional quality inspection personnel. After the machine is installed, the machine will be accurately debugged, and then the cutting accuracy will be tested in actual work. At least 48 hours of running test must be carried out before shipment. |

Jinan Shilai Technology Equipment Co., Ltd. specializes in the R&D and production of CNC cutting machines. Products are mainly used in various flexible material industries and fields such as automotive interiors, clothing, home furnishings, advertising, carpets, composite materials, cartons, sealing gaskets, and foam linings.

Shilai Technology wins the market with service, builds the brand with quality, and wins the trust and praise of customers with its excellent technology, professional management team, affordable prices, considerate and thoughtful services, and fast and complete service network. , products are exported to more than 80 countries around the world. We are your trustworthy machine supplier and partner.

1. We offer manuals and videos for our gasket making machine installation and operation.

2. Machine was tested well by the quality inspection team before delivery.

3. We offer 3 years warranty for the machine. We will offer the broken parts free of charge in warranty.

4. Our machine got CE, ISO, and FDA certifications. And we have export authority.

5. We provide lifetime maintenance service for the machine.

|

|

|

Multifunctional toolsThe combined cutter tools can cut wide range gaskets of various materials, hardness, and thickness | Fully welded bodyWelded from square steel tubes, heat treated, and milled on five sides. Ensure the accuracy and strength of the body | Vacuum tableThe overall aluminum bellows table with a thickness of 40mm. High strength, high precision, and strong adsorption force. |

|

|

|

High-precision guide railSLCNC gasket cutter machine adopts high-precision racks and guide rails. High accuracy, wear resistance, and low noise. | Servo motors and driversSLCNC gasket cutting machine uses Japanese servo motor and driver, high precision, long life, and high torque. | Vacuum pumpHigh suction vacuum pump, strong suction, firm fixing of materials. With a muffler to reduce noise. |

|

|

|

Safety devicesThere are four corners emergency stop switches and infrared induction switches to protect the operator and the machine. | CNC SystemThe touch screen integrates the settings and operations, the gasket cutter machine is simple and convenient to use, supports multiple languages | Wooden PackagingThe complete equipment is packed in a fumigation-free wooden box to protect the machine from damage during transportation. |

Gaskets are widely used in industry and play an important role. Gaskets are used in mechanical equipment and pipelines as long as there is fluid. Gasket material includes rubber, silicone, asbestos, asbestos, PTFE, non-asbestos and other materials. SLCNC gasket cutter machine can cut these non-metallic gaskets very well.

SLCNC gasket cutting machine can be equipped with multiple cutting tools at the same time. Because the thickness and hardness of the gasket vary, the cutting tools required are different. Our gasket making machine can combine multiple cutting tools together to meet your wider cutting requirements.

Cutting tool combination

The combination tool broadens the cutting range of gaskets. No matter thick or thin, hard or soft, one SLCNC gasket cutting machine can cut them all.

Knife cutting tool

Used to cut soft, hard but thin gasket materials, such as rubber, silicone, and thin asbestos.

Milling cutting tool

Used for cutting hard and thick materials, such as thicker PTFE, asbestos, etc.

| Easy operation The CNC gasket cutting machine is a CNC knife cutting machine. Unlike the die-cutting processing method, it does not require a mold. Only CAD electronic graphics are needed to automatically cut gaskets of various shapes by a knife blade. For customized and small batch gasket production, it can shorten the production cycle, save the cost of molds, and graphic storage is much simpler and more convenient than mold storage. |

| High precision SLCNC gasket CNC cutting machine adopts a high-speed drive and transmission method. Japanese servo motors and drives, Taiwan guide rails and helical racks ensure the accuracy and efficiency of processing. And ensure that the equipment has a long service life and a low failure rate. |

Material automatic fixing SLCNC automatic gasket cutting machine uses vacuum adsorption to fix the material. The vacuum pump automatically starts and stops with the cutting process. When the cutting starts, the vacuum pump automatically starts, and when the cutting ends, the vacuum pump automatically stops. This way of fixing the material is simple and convenient, and will not damage the material. | |

| Safety SLCNC gasket making machine does not require manual operation during the cutting process. It not only saves labor costs, but is also safer. In addition, the machine is equipped with a four-corner emergency stop switch and an infrared sensor switch. Ensure the safety of operators and equipment. |

| Nesting software saves material SLCNC gasket cutting equipment has automatic nesting software that can control parameters such as the gap of typesetting. The material utilization rate can be calculated, and the material utilization rate can be improved to reduce production costs. |

Model | CZ - 1625 |

Work Size | 1600mm x 2500mm/other size |

Cutting Table | auto feeding table / flat table |

Warranty | 3 years for machines |

Cut Speed | ≤ 1600 mm/s |

Cut Thickness | ≤ 100mm |

Location Precision | ≤ 0.01mm |

Safety Device | infrared sensors, responsive, safe and reliable. |

Material Fixed Mode | vacuum table |

Support software | Corel draw, AI, Auto cad and etc |

Motor and Driver | Japan Yaskawa / Panasonic |

Support Format | plt, ai, dxf, cdr, hpg, hpgl, etc |

| Precision designSLCNC has a professional design team. The whole gasket cutting machine and each component are carefully designed. Ensure that the mechanical structure of the machine is reasonable, the rigidity and precision of the components meet the production requirements, and are easy to install and repair in the future. |

| Precision machiningThe installation surface of the bed is processed by five-sided milling to provide a high-precision benchmark for subsequent installation. The installation parts on the machine, such as the motor seat, and the connecting parts, such as the gantry bracket, are all processed by the CNC machining center to ensure the accuracy of the machine parts. |

| Precision installationSLCNC has a stable and skilled production team. There are strict technical requirements for the installation of components. The installation accuracy of the transmission components is measured and debugged by a dial indicator to ensure the installation accuracy of the machine. |

| Precision testingSLCNC has professional quality inspection personnel. After the machine is installed, the machine will be accurately debugged, and then the cutting accuracy will be tested in actual work. At least 48 hours of running test must be carried out before shipment. |

Jinan Shilai Technology Equipment Co., Ltd. specializes in the R&D and production of CNC cutting machines. Products are mainly used in various flexible material industries and fields such as automotive interiors, clothing, home furnishings, advertising, carpets, composite materials, cartons, sealing gaskets, and foam linings.

Shilai Technology wins the market with service, builds the brand with quality, and wins the trust and praise of customers with its excellent technology, professional management team, affordable prices, considerate and thoughtful services, and fast and complete service network. , products are exported to more than 80 countries around the world. We are your trustworthy machine supplier and partner.

1. We offer manuals and videos for our gasket making machine installation and operation.

2. Machine was tested well by the quality inspection team before delivery.

3. We offer 3 years warranty for the machine. We will offer the broken parts free of charge in warranty.

4. Our machine got CE, ISO, and FDA certifications. And we have export authority.

5. We provide lifetime maintenance service for the machine.